The Rising Demand for Reliable Power Supplies in Industrial Applications

Automation is not applicable only to big factories in the modern industrial environment. Indian industries are relying more on constant and continuous power, whether in small control panels or in an entire production line. PLCs can be reset by momentary changes in voltage less than a second long to interfere with data transmission or even turn off a whole process line.

To those industries that have a tight turnaround time on the delivery schedule, such interruptions can prove costly. Research in the various manufacturing industries has shown that industrial downtimes may incur losses in the form of crores per hour, depending on the size of production and the complexity of the processes.

This is an ever-increasing threat, which has posed a great pressure on the need for a dependable power supply for industrial use. Surviving blackouts is no longer the question. The clean, continuous and controlled power is essential in industries to ensure that productivity, safety and reliability of the system stay up to date. As a business industrial electronics distributor, SS Electronics collaborates effectively with engineers and procurement to mitigate such developing power problems.

The Motives that Drive the Must to Have Unbreakable Power

This demand is being fuelled by several structural changes in the industrial processes.

Critical Influencing Factors on the Reliability of Power Requirements

Quick automation and adoption of Industry 4.0

PLCs, VFDs, HMIs and industrial sensors are very susceptible to voltage dips and electrical noise.

Control systems and data that are mission-critical

SCADA, MES, and industrial servers need power that is not interrupted so that there is no corruption of data or wastage of time rebooting the system.

Instability of the grid and energy transformation

Added renewable energy integration has brought variability in voltage and frequency in industrial grids.

The productivity expectations and supply chain pressure

Even one shutdown may have an impact on several downstream processes and customer commitment.

Regulatory compliance and safety

The loss of power in process industries may result in the absence of safety and a lack of adherence to quality standards.

More than a Blackout: The Unseen Fixed Costs of Low Power Quality

False power causes long-term operational risks that cannot be seen.

Industries Commonly Experience the Following Consequences

- Loss in production and wastage of raw material

- Early wearing out of drive motors and electronic boards

- System reprogramming due to loss of data

- Late delivery schedules are impacting customer confidence

Power quality impact overview

|

Power Disturbance |

Operational Impact |

Business Risk |

|

Voltage dips |

PLC resets and line stoppage |

Productivity loss |

|

Power surges |

Component damage |

High repair cost |

|

Harmonics |

Equipment overheating |

Reduced lifespan |

|

Power outages |

Complete shutdown |

Missed commitments |

Developing a Power Protection Safeguard Strategy

The Reason that Generators are Not Sufficient

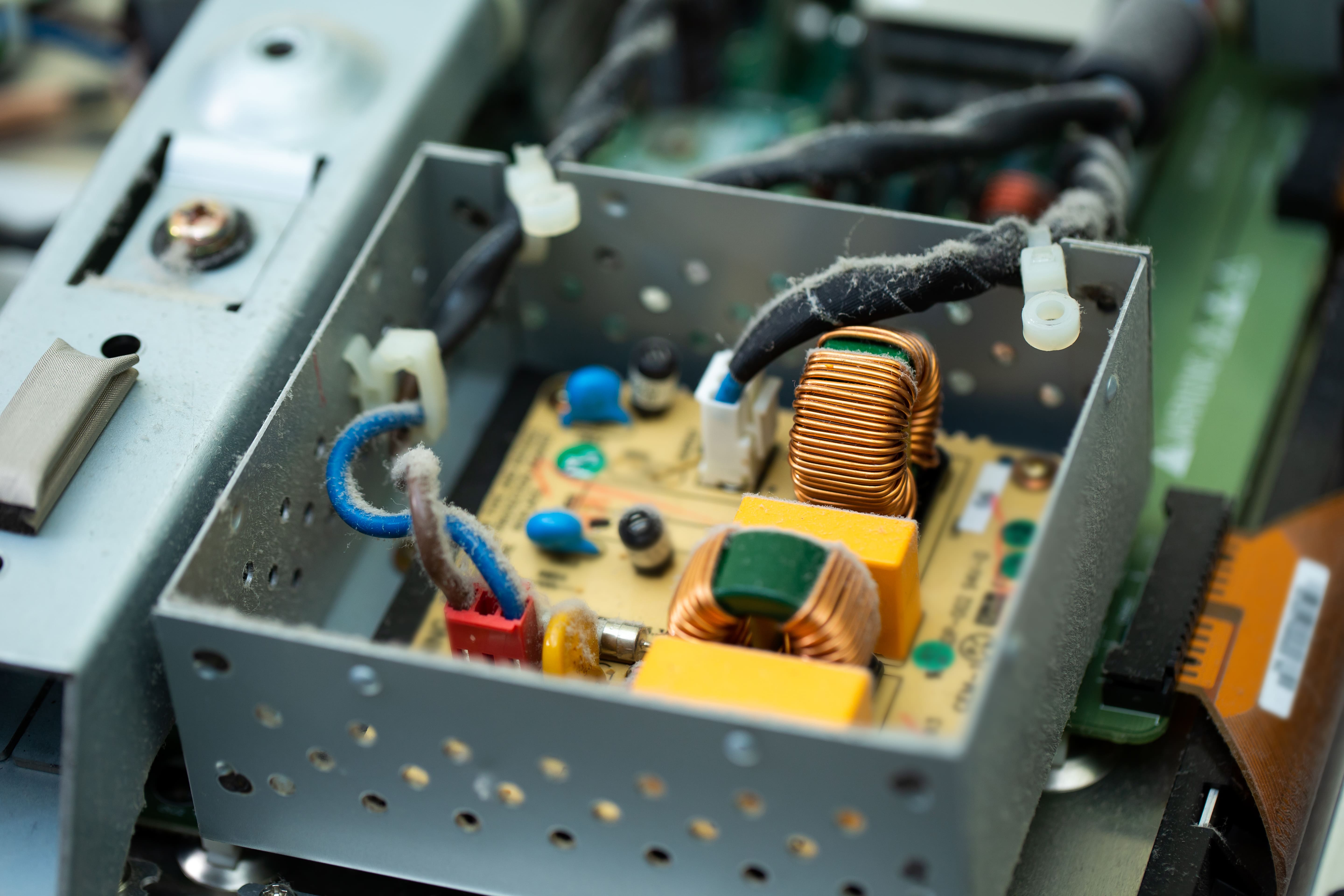

Generators are available as alternative sources, but need time to come online. There is no protection of sensitive electronics during this period of transition. This is well solved using Uninterruptible Power Supply systems that provide immediate power continuity.

The modern industrial configurations are more dependent on superior switched-mode power supplies of globally recognised brands like Mean Well that have gained popularity in control panels, automation systems and in instrumentation processes. Such solutions ensure the stability of voltages and the stability of systems when used together with effective power protection.

What the Modern Industrial Power Systems Ought to Provide

- Immediate reaction to power failures

- Constant voltage and frequency regulation

- Filtering to clean output harmoniously

- Interoperability with automation and control equipment

Critical Industrial Characteristics

- Durable structure in high-temperature and dusty environments

- Options to reduce the risk of failure

- Easily expandable capacity to accommodate plant expansion

- Eco-friendly functioning to minimise the overall expenditure

How to Check Your Power Protection Requirement

The process of choosing the appropriate power solution begins by having a feel for operational risk.

Assessment Practicums

- Note some crucial loads, including control panels, servers and safety systems

- Track location-specific power quality problems

- Specify the permissible start-up or safe shutdown time of the generator

- Engage the help of proven industrial electronics distributors, such as SS Electronic,s to provide technical advice

Typical runtime requirements

|

Application Area |

Recommended Runtime |

|

Automation panels |

5 to 10 minutes |

|

SCADA and data systems |

15 to 30 minutes |

|

Safety-critical circuits |

Continuous or redundant |

Conclusion: Consistent Power as a Strategic Competitiveness

With the further introduction of automation to the Indian industries, the use of digital monitoring and interconnected systems, the significance of a good power supply is ever-increasing. Power reliability is not a support feature anymore, but one of the main functioning requirements.

Investments in quality power solutions, a trusted brand like Mean Well and professional sourcing by trusted suppliers like SS Electronics can allow industries to gain by minimising downtime, equipment protection and long-term operational efficiency.

Dependable power is not costly. It is an investment in strategic productivity, safety and business continuity.

Need to be Associated with the Best Company?

Dissociations in power are usually not even realised until they create significant instability. Costly downtime can be avoided by proactive assessment and the appropriate use of a power protection strategy.

Meet with SS Electronics to evaluate your power needs in industries and find trustworthy power providers to help you achieve long term stability in operations.